Community center

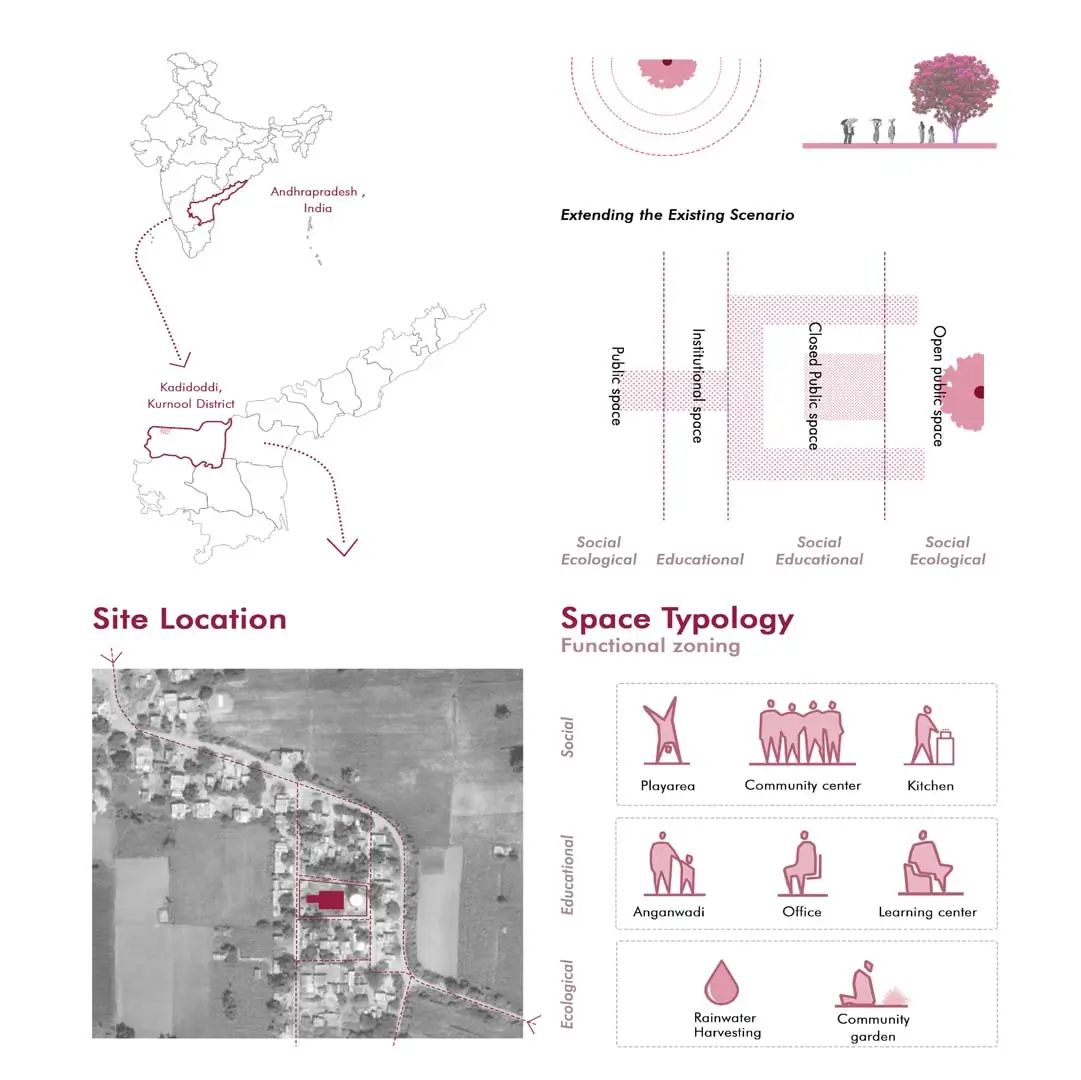

Kadidoddi, Andhra Pradesh, India

Description

DESIGN TEAM : Ar. Manish Mahendran, Ar. Jayanth, Ar. Dinesh, Ar. Basil Vignesh

POSITION : Honorable Mention (top 10)

CONTEXT : Kadidoddi is a secluded village situated beside the banks of the Tungabhadra River, on the outskirts of Andrapradesh. It is home to 785 people in total. The village of Kadidoddi has a 35.82% literacy rate, which amply demonstrates the necessity for educational hubs that advance both education and literacy rates. Kadidoddi village has roughly 151 homes. The site, which sits in the middle of Kadidoddi Village, functions like a square and encourages people to gather there for meetings, work, and play.

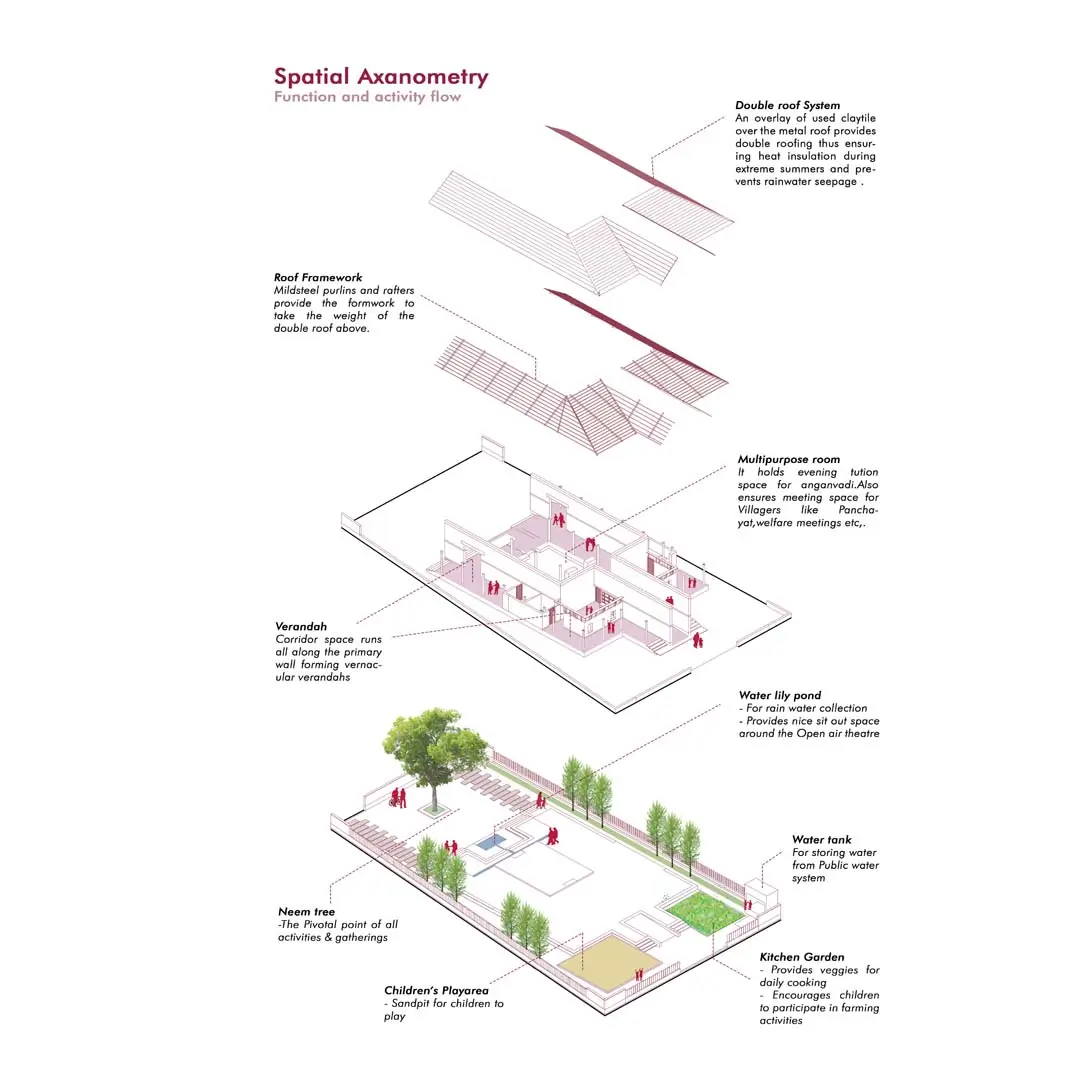

IDEA : Community Gatherings: The Neem tree at the site is a meeting point where villagers gather for social, cultural, and communal activities. The shade provided by the trees is ideal for panchayat meetings, festivals, and informal gatherings. Educational Spaces: Also schools and informal educational gatherings are held under the shade of large trees. This tradition provides a natural, comfortable environment for learning. The design evolves, extending the actual scenario.

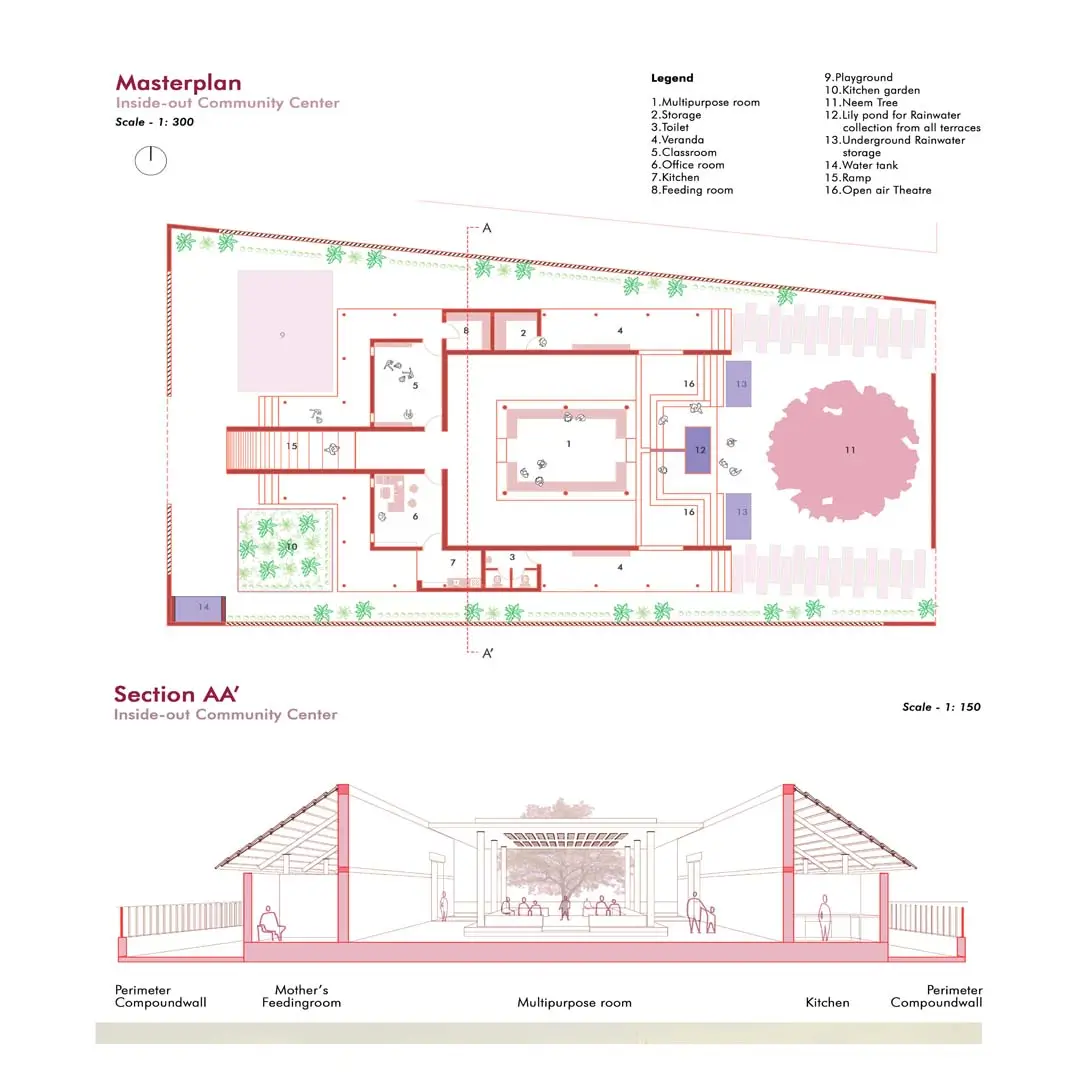

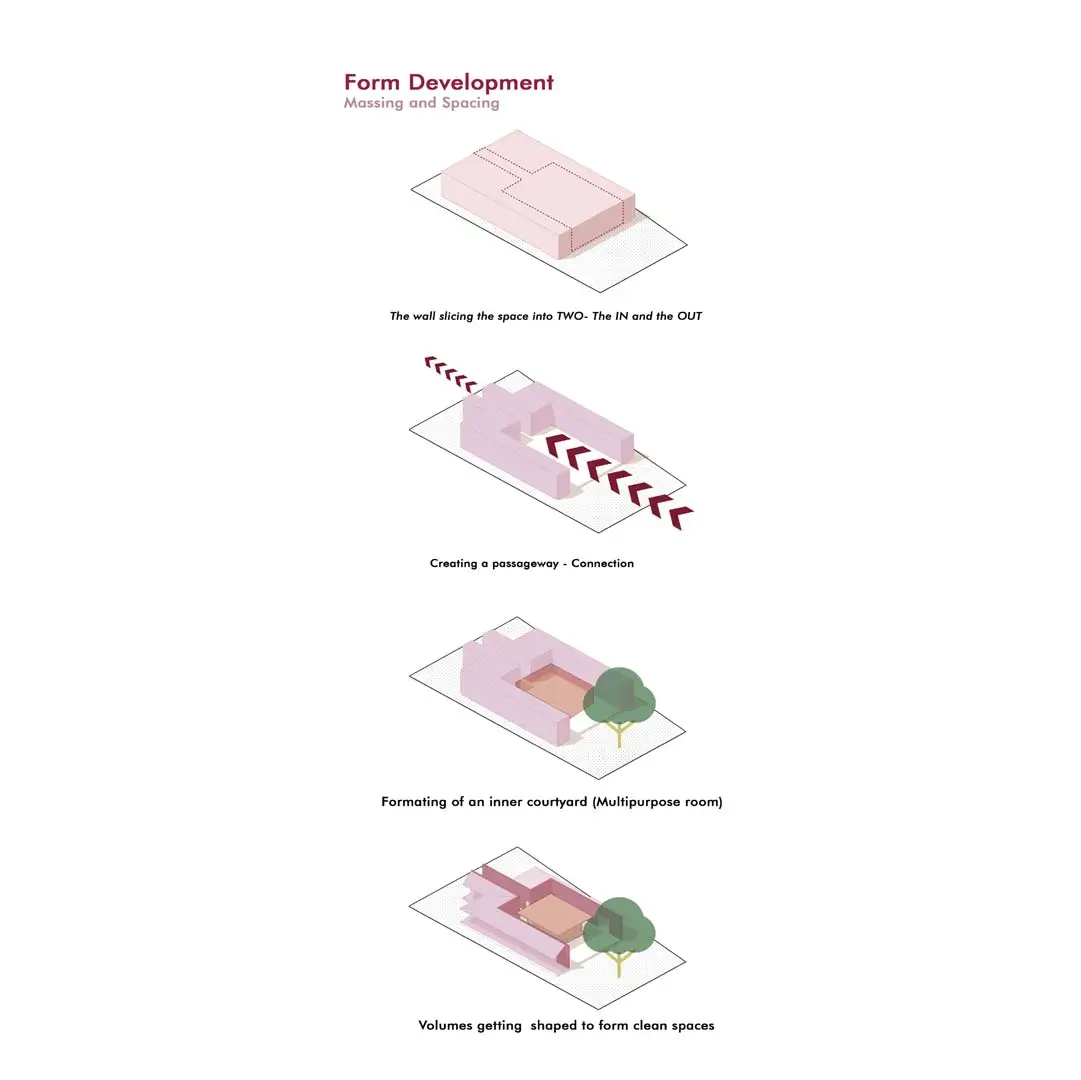

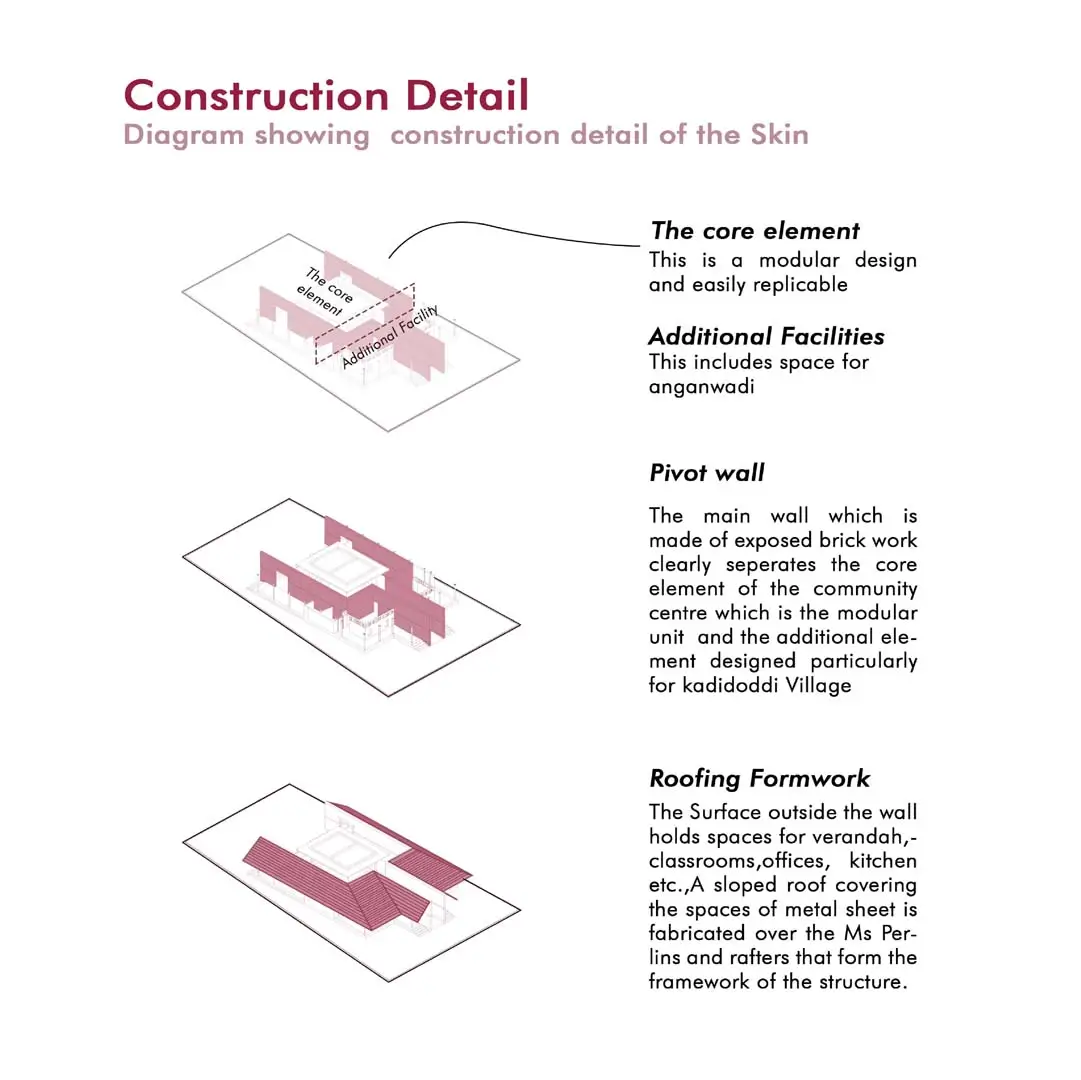

INSIDE OUT : The main wall clearly separates the core element of the community centre which is the modular unit and the additional element designed particularly for kadidoddi village.

The Core element : The core element includes the multipurpose hall, Toilet, storage room, Verandah, Neem Tree, Lily pond, rainwater harvesting sump.

Additional element : The additional element includes anganwadi, Feeding room, Office, Kitchen, Kitchen Garden, Play area.

CONSTRUCTION TECHNIQUE

The wall : The core wall is built of exposed country bricks, and the partition walls are plastered brick walls above stacked with kadappa louvers for ventilation.

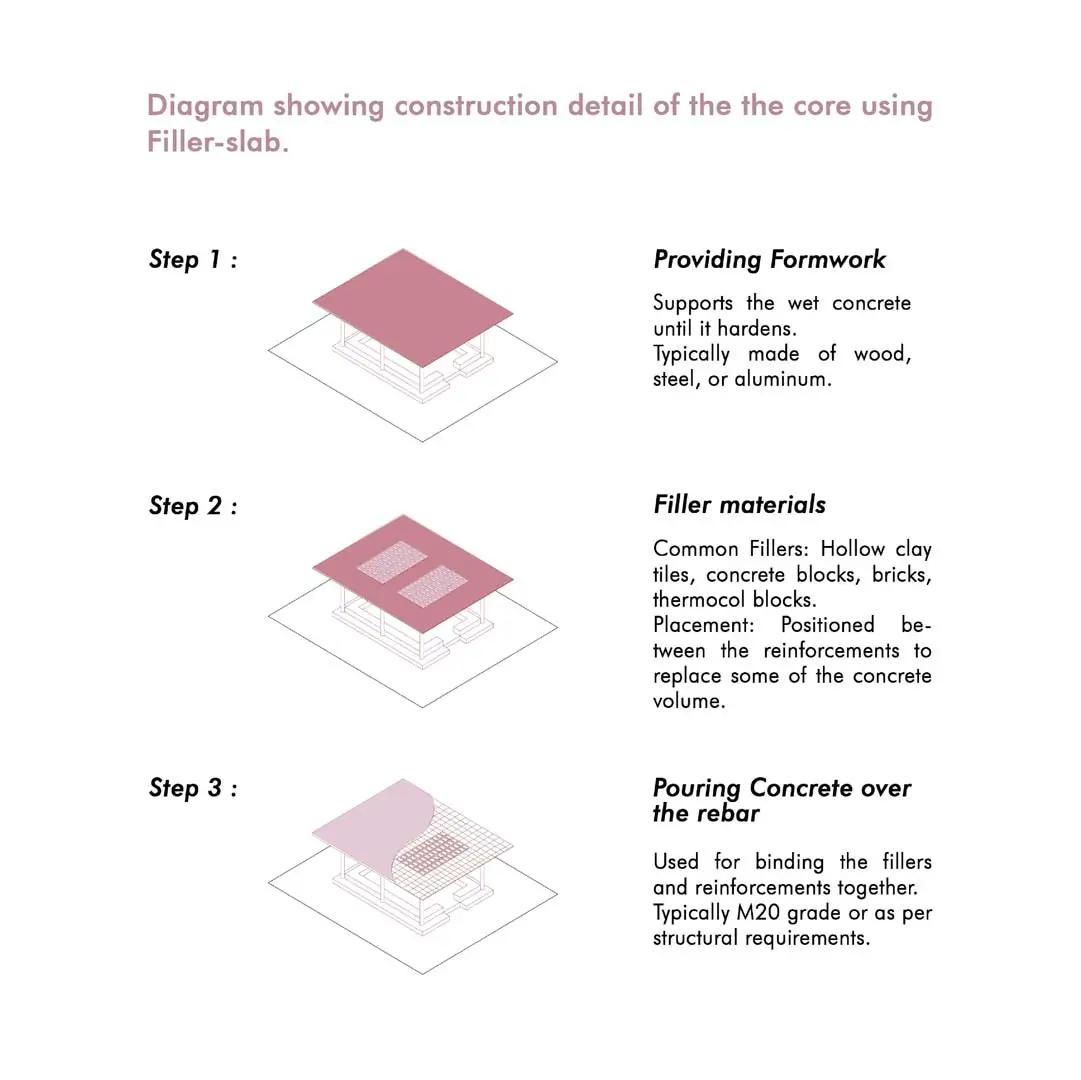

The Roof : An overlay of reused clay tile over the metal sheet roof provides double roofing, thus ensuring heat insulation in the extreme summer and preventing rainwater seepage. Filler slab for community hall, reused clay tiles are used as a filler material ensuring it significantly reduces the overall dead load of the structure, making it lighter and potentially more economical.

The Columns : The circular RCC columns are shuttered with round precast RCC rings. In the process mentioned earlier, no large machinery will be used. Instead, volunteers and members of the local community will work together to create the structure.